Company Profile

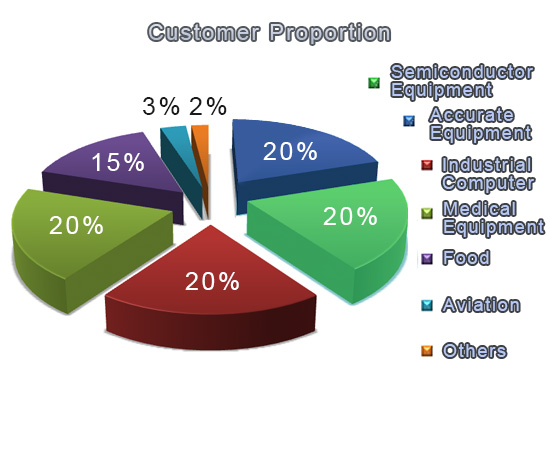

JIH YU Accurate Industrial Corporation was founded in Banqiao District, New Taipei City in 1997. Initially, our company focused on producing sheet metal samples of computer structure and accurate electronic equipment structure production. Simultaneously, we pioneer our competitors and expand the OEM production scale into medical equipment and industrial computer case sheet metal. Our products are with high reputation among our customers.

For the sake of our company proliferated, we increased funding, expanded our plant, and moved to Sanlong St., Shulin Dist., New Taipei City in 2001. Besides, we included OEM production of semiconductor TFT equipment organization of sheet metal sample. Meanwhile, we pursued OEM production of sheet metal holistically; we increased investing NCT stamping sheet metal factory and stamping mould factory.

Due to European Union environmental regulation, since 2005, we embedded green environmental regulation (RoHS) to protect the global environment. In 2020, we increase funding and expand the factorial size and move our company's location to San Jun Street, Shulin District, to integrate each department and increase equipment.

Milestone

● 1997- JIH YU was founded in Banqiao City.

● 1998- PC IT mechanical sheet metal sample production.

Accurate electronic production equipment, organizational sheet metal production.

Medical equipment organizational sheet metal production, IPC case sheet metal OEM production.

● 1999- Increased funding and expanded scale of OEM production regarding medical equipment.

Embedded MRP management operating system and increased advanced sheet metal produced equipment.

● 2000- Enhance professional OEM production and accept outsourced producing ATM sheet metal informational tour machine production.

● 2001- Increase funding, expand the scale and move to Sanlong street, Shulin City.

● 2002- Include semiconductor TFT produced equipment and organizational sheet metal OEM production.

● 2003- We invested in NCT stamping sheet metal factory and stamping mould factory to make the sheet metal OEM production more holistic.

● 2004- Adopt sheet metal production of aviation equipment regarding OEM production.

● 2005- Adopt green environmental regulation (RoHS).

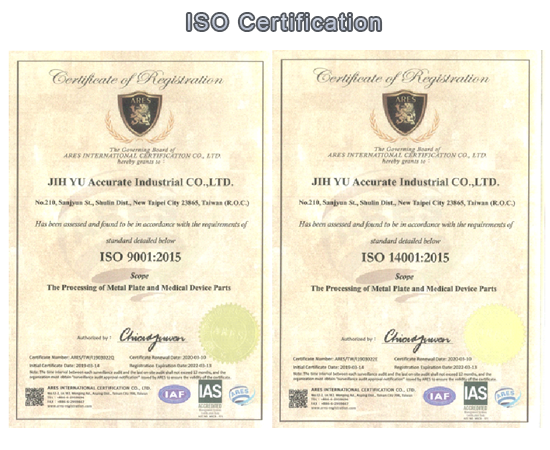

● 2006- Pass ISO 9001 and ISO 14001 certification.

● 2007- Increase plant to 3,305.8 square meters.

● 2008- Enhance ERP management operating system and incorporate all production lines into the ICT management system and being able to handle the production process accurately.

● 2009- The procurement of F1 Magnetically Levitated Linear laser cutting machine.

● 2012- Add LC2012 C1NT(01) laser / punching compound machine.

● 2012- Add HDS1303 NT servo hydraulic composite press machine.

● 2016- Build the new Plant.

● 2019- Add automatic mold exchange device bending machine, automatic rack storage cabinet and the three-dimensional measurement arm.

● 2020- The new plant was relocated at # 210 Sanjun Street, Shilin District, New Taipei City. The factorial areas reach 7,500 square meters, and we can offer more innovative service in the future.

● 2021- AWS CWI Welding Inspectors.